Commercial Building Restorations Assessment Testing

In a typical commercial building restorations project numerous conditions have to be assessed. In order to meet the specifications and trade best practices tests of many kinds can be conducted, some by trained test technicians in the field and in laboratories and others by the mechanics as they complete their work or prepare for it.

Coating Adhesion

SSPC (Society for Protective Coatings) Adhesion Test

Webinar Powerpoint Presentation

Defelsko Positest Pull Off

Adhesion Tester Instructional Video

Moisture In Cured Concrete and Wood Floors

Articles on moisture in concrete at Formulators.com

- Epoxy Sealants & Osmotic Blisters -A Loaded Gun You Should Worry About

- Synthetic Gypsum is still Gypsum

- Precision & Bias Doesn’t Exist for Concrete Moisture Testing?

- Is Vinyl Getting a Bad Wrap?

- The Problem with Moisture Mapping A Question of Qualitative vs Quantitative

- Moisture Testing Without a Sub-Slab Moisture Barrier?

- We Don’t Measure Moisture… We Calculate Risk

- The Warranty Game

- Einstein & MVER – How Elevated Moisture Happens

- pH & How to Formulate Against It

- Novel Method for Evaluating Hydrolytic Stability and Moisture Resistance in Flooring Adhesives

- Adhesive Re-Emulsification Myth Contrary to popular belief modern adhesives do not re-emulsify…

- OSHA Fact Sheet – Worker’s Exposure to Respirable Crystalline Silica: FINAL RULE Overview

Delmhorst Instrument Company

Manufacturers of pin and pinless moisture meters for determining the moisture content of wood flooring, concrete slabs, crops, paper and leather.

How to Moisture Test Concrete Floors

MVER, Moisture Vapor Emmission Rate testing

The “Tape Down Test”, ASTM D 4263 and the calcium chloride test, ASTM F 1869 are explained in a video. These or similar tests using moisture detection instruments are needed when coating concrete floors with non breathable materials such as high solids epoxies or 100% solids polyurethane. Moisture tests are also needed when laying wood and some laminate floors.

Sealant Adhesion

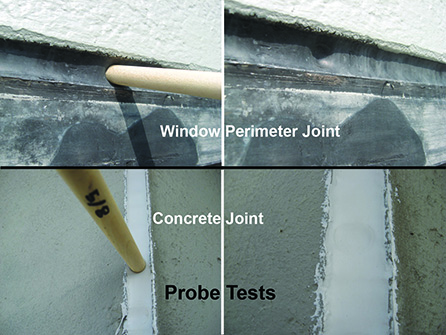

Probe Test For Sealant Adhesion

The “Probe Test” is a standard and effective, non-destructive method for evaluating the condition of a sealant joint. It is done by pressing a rounded, wooden dowel that is about 1/8″ smaller in diameter than the width of the joint into the cured sealant to a depth of about one half of the joint width. To pass the test the material must remain adhered to the substrate and not exhibit any cohesive failure.

“Pull Tail” Test for Sealant Adhesion

In this video silicone sealant installed between two precast panels is pulled from the joint to verify adequate adhesion to the substrate. The criteria for a successful test is whether or not the sealant pulls out of the joint. Here, the sealant didn’t separate from the substrate so the installed joint passed the test, which will be repeated at specified areas or intervals throughout the project.

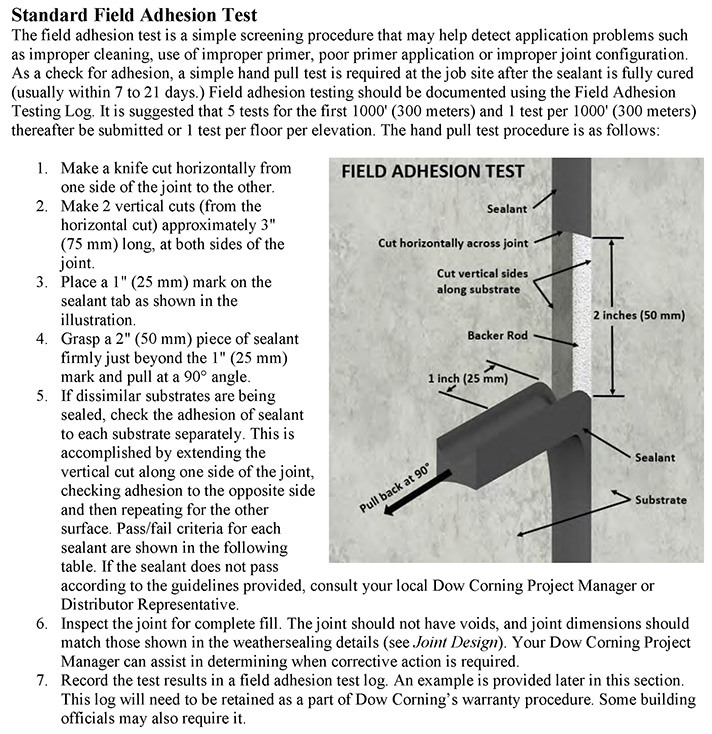

“Pull Tab” Test For Sealant Adhesion

The “Pull Tail” test described above is for joints that are bound on either side by the same substrate. Window perimeter joints, and others, will have different materials on either side of the joint and these need to be tested one side at a time. In a Pull Tab test one side of the joint is tested at a time. This is done by cutting the sealant along one side of the joint, cutting the joint to create a pull tab and pulling the tab away from the joint until it either tears out of the joint or separates from the substrate on the side that wasn’t cut. If it peels away from the substrate the installation is unsatisfactory and the joint has to be redone once the reason for the failure has been determined and corrected. On the other hand if the sealant tears, i.e., if it fails cohesively than the joint is a good one in regard to adhesion.

Test Equipment and Materials

Positest AT-A Automatic Coating Adhesion Tester from Montipower Test Equipment & Specialty Tool (M-Test) Humble, Texas, USA

Adhesion tester measures adhesion strength of coatings to metal, wood, concrete and other substrates

Epoxy adhesive for the coating adhesion test

Huntsman Araldite 2011 Slow-Setting All-Purpose Epoxy (aka AW106 /HV953U) for attaching the “dolly” to the coating

Hygometer by Amphenol

Protimeter Hygromaster 2 Thermo-Hygrometer: Infra-red non-contact surface temperature supplies data for psychometric calculations, which, among other things, determine formation of surface condensation. Data logging functions. Simple to use interface with color display. Fast temperature and humidity response. Replaceable humidity and temperature sensor. Highly accurate

PRG – Preservation Resource Group

Products and Tools for Architectural Preservation. For building evaluation they have crack gauges, crack monitors and accessories, such as calipers, crack points and adhesives, moisture meters, hammer driven pin electrodes, Rilem tubes for water absorption testing and the putty for affixing them to walls and floors. They also sell flood clean-up biocides and odor control chemicals, wood preservation products including insect control materials, products for mold prevention and remediation, boracides and borates for various uses, fire retardants, cleaners and products for odor elimination and borates and mineral salts for insect control.

Test Standards

ASTM and AAMA (American Architectural Manufacturers Association) Tests

RM Group provides this list of test standards for the water penetration and air infiltration tests for which their products are built.

Repair Mortar Test Procedures by Conproco

Simple 3D and 2D graphics illustrate ASTM tests for repair mortar compressive strength, tensile strength, flexural strength and shrinkage.

Water Absorption Test With Rilem Tubes

RILEM Tube Test for Water Absorption – Pecora Corporation Technical Bulletin PEC 170

Instructions on using RILEM tubes for field water-repellency evaluations, guidelines for interpreting the resultant data and how to make the correlation between the water level in the tube in milliliters and the velocity of wind-driven rain.

Testing the Test: Water Absorption With RILEM Tubes

This article in the August, 2013 edition of “The Construction Specifier” is a fairly comprehensive analysis of the RILEM Tube Test, which is used to determine a surface’s resistance to water absorption.

Durable Waterproofing for Concrete Masonry Walls: Field Testing Methods of Water Repellency

Two test methods are described in this June, 2014 “Construction Specifier” article: Droplet Testing and RILEM Tube Testing. The RILEM Tube Test permits testing of water absorption on vertical surfaces. Test with the standard RILEM Tube simulates a 98 mph driving rain because of the water head it contains. The short RILEM Tube, which holds approximately 2 ml of water, simulates a 60 mph wind. The Droplet Test is done on a horizontal surface.

Water Penetration Testing

RM Group Products and Services

The Sprayrack™ Rain Maker™is used to conduct water penetration tests of windows and other building components according to ASTM standards. The company also manufactures equipment and accessories for air infiltration testing.