Silicate Mineral Paint

Silicate mineral paint, also called liquid silicate or simply mineral paint is the invention of the Bavarian, Adolf Wilhelm Keim. In response to his sovereign, King Ludwig I, who desired fine lime fresco work comparable to what’s found in Italy, Keim developed a product that would survive the harsh climate of the Alps. The combination of water glass (potassium silicate solution) with inorganic color pigments was the result; a paint that both penetrates and chemically reacts with the mineral substrate, becoming integral to it. The new surface can never peel or blister. It is highly weather resistant, durable and colorfast.

Buildings painted in the 19th century are still as King Ludwig wanted them. The “White Eagle” Inn at Stein am Rhein and the City Hall, Schwyz, both in Switzerland were painted in 1891. Facades in Oslo done in 1895 and in Traunstein, Germany (1891), remain in excellent condition today.

Inorganic Coatings For Restoration

Silicates are inorganic and therefor have no volatile organic compounds. “VOCs” pollute the atmosphere and can make coating application a hazardous activity but according to the author of this article safety and environmental friendliness aren’t the only advantages of silicate paint.

Mineral Silicate Paints Tops for Durability

This article lists the benefits of silicate paints including surface quality and that they are solvent-free and very durable (125 years!), low-maintenance, breathable, colorfast, non-combustable, mold resistant and resistant to acid rain. They are also expensive. Four manufacturers are cited in the article: Keim Mineral Systems, Silicote USA, Eco-house and Edison Coatings, Inc. The prices cited are $65 to $90 per 5 kg (0.9 gallon) for Keim products, which are sold by the 1 kg and 5 kg cans, and 25 kg (4.5 gallon buckets.) The installed cost averages about 45¢/sq ft of wall ($4.85/sq m) for a single coat and 90¢/sq ft ($9.70/sq m) for two coats. Eco-House, which manufactures mineral silicate paints in Fredericton, New Brunswick, Canada retails their paints for about US$235 for a 5-gallon (19 l) pail. While less expensive than Keim products, this is still considerably more expensive than conventional interior and exterior paints.

Silicate Mineral Paint on Wikipedia

Manufacturers of Silicate Mineral Products

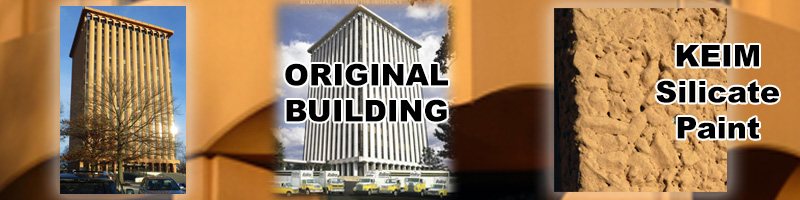

KEIM Mineral Coatings

Invented potassium silicate mineral paint in 1878. The catalyst for Adolf Keim’s development work was King Ludwig I of Bavaria. This monarch had a great passion for the arts. He longed to have examples of fine Italian lime frescoes in his own kingdom but the harsh climate north of the Alps destroyed them within a short time. He appealed to his Bavarian scientists to develop a paint that would offer the appearance of lime fresco art yet resist the harsh weather. The unique solution to these requirements was embodied in Keim’s invention – a liquid silicate coating that chemically binds both the color pigment and the applied surface.

Cathedral Stone

Products include mineral silicate paints / coatings, repair mortar for historic restoration, penetrating sealers, coatings, fixatives and tools for masonry and stone construction and repair.

Eco-House, Inc.

A Canadian company that manufactures silicate mineral coatings, fine art supplies and natural wood finishes.

Edison Coatings, Inc. Everkote 300 Mineral Coating System

EverKote 300’s is produced by fusing potassium carbonate with silica at high temperature producing soluble silicate, which can be dissolved in water to produce a liquid “waterglass”. On suitable substrates, such as stone, concrete and masonry, it penetrates and reacts to form a hard, insoluble silicate. It can also increase substrate hardness, particularly in cementitious materials. When applied to materials containing Portland cement, the silicate reacts with incompletely hydrated cement particles, converting unreacted calcium hydroxide (or hydrated lime) to harder calcium silicate hydrates.

ConcreteSealersUSA

Lithium Silicate and Sodium Silcate penetrating sealers are breathable sealers that react with cementitious material to increase its density, hardness and strength, reduce water absorption tendency, reduce dusting and efflorescence and decrease maintenance requirements. The effect on the cementitious material is what distinguishes this category of sealers from others and it can effect the texture making a floor more slip resistant or a wall more polished if the sealer is applied with a scrubber or polisher.